Planet first: Setting the standard in sustainability

Published by Admin on

Apr 22, 2021 9:00:00 AM

Consumers worldwide are demanding sustainable products and awareness of eco-friendly or sustainable products is growing around the world and across all income brackets. Every consumer product industry is adapting not just to meet the customer’s needs but because there’s growing awareness around the benefits of the manufacturing process and products being kinder to the planet and improving our relationship with our natural environment.

The interest in environmentally sustainable furniture has been growing in recent years and it’s a trend that shows no sign of slowing down. A recently published study by PricewaterhouseCoopers (PwC) showed that sustainability is a crucial factor among three-quarters of consumers buying furniture. From materials to the creation process, consumers are doing their homework to make sure the furniture they buy is not only high quality but also environmentally friendly.

Let’s explore the touchpoints where furniture manufacturers can improve sustainability in their design.

Concept

The true foundation for sustainability lies in the concept of the furniture piece itself. Ideally, the design should be simple but highly functional, using few but high-quality materials and it should be able to be made with as little energy and as little waste as possible. Laying the foundation for a sustainable product includes looking at the lifespan of the product and ensuring it can be either recycled or up cycled are further ways of reducing waste and ensuring sustainability.

Design

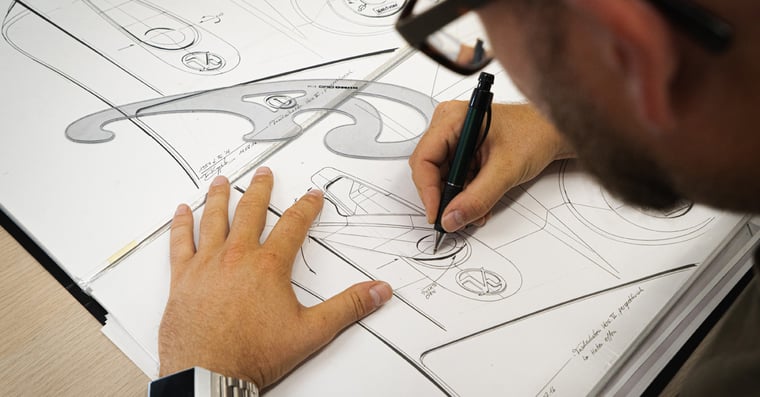

This sustainability demand at the onset poses a challenge for furniture designers and manufacturers. Now that they know the parameters of the design, it’s down to imagining and physically designing this furniture and it’s here where technology can boost sustainability.

Twinbru’s 3D modeling service takes the initial design sketch and creates a digital model where the proportions and dimensions of the design can be accurately visualised. There are a number of advantages to choosing the digital route for furniture design:

- It saves time. The 3D model can be created in a relatively short period of time and eliminates the enormous time expense in creating physical prototypes to see the dimensions of the design.

- It drives efficiency in the prototyping process because a change in shape or measurements doesn’t require an entirely new prototype to be built.

- There’s no waste of materials by creating multiple prototypes as several prototypes can be modelled digitally.

- It boosts accuracy and reduces waste because the measurements are accurate in a 3D model meaning that materials orders will be exact.

- It’s more cost effective. The saving in materials makes digital visualisation and modeling an extremely attractive solution for any furniture manufacturing enterprise, big or small.

Sourcing

With the design process going digital, the next touchpoint where sustainability is key is in the materials themselves. Sourcing is critical and textiles and fabrics that are environmentally friendly are becoming an industry standard.

There are, in fact, certain standards and certifications that are important to remember.

REACH Compliant

Bru’s fabrics in Twinbru’s fabric library consistently meet REACH regulations. REACH (the Registration, Evaluation, Authorisation and Restriction of Chemicals) is a regulation of the European Union, adopted to improve the protection of human health and the environment from the risks that can be posed by chemicals.

STANDARD 100 from OEKO-TEX®

The fabrics in Twinbru’s extensive fabric library comply with the STANDARD 100 from OEKO-TEX®. The STANDARD 100 means the fabric is completely free from harmful chemicals and safe for human use and performs uniformly around the world by the independent OEKO-TEX® institutes. All factors of the production of the fabric come into question, and this includes the dye that’s used, the threads the fabric is sewn with, the lining used, any print patterns, and accessories such as tassels and buttons.

Global Recycled Standard (GRS)

New collections from FibreGuard and FR-One comply with the Global Recycle Standard (GRS). This is an international, voluntary, full product standard that sets requirements for third-party certification of Recycled Content, chain of custody, social and environmental practices, and chemical restrictions. The goal of the GRS is to increase the use of recycled materials in products and reduce/eliminate the harm caused by its production.

Organic Content Standard (OCS)

OCS is a certification awarded to goods that are guaranteed as containing organic content such as organic cotton. Each party involved in the chain of production, from yarn supply through to finished goods, is closely audited and controlled to ensure the item contains genuine organic content. Based on their composition, fabrics are either awarded the “Organic Content Standard 100” for fabrics containing more than 95% organic fibre, or the “OCS Blended – Organic Content Standard” for fabrics containing between 5% than 95% organic fibre.

Manufacturing

At this touchpoint, furniture manufacturers can look at machinery and software that can minimise waste and enhance efficiency. It’s also worth investigating ways to save energy through solar power, adopting processes that require little to no water, and implementing fair production practices that include good working conditions and wages that prioritise the well-being of staff.

How Twinbru contributes to sustainability

Digital fabric twins are the offering Twinbru has that can actively contribute to greater sustainability within the furniture manufacturing industry. With our digital fabric, we’re able to showcase new or upcoming fabrics without sample books and before stock arrives in the warehouse. This change negates the need for physical samples and helps reduce carbon footprint through efficiency. Digital samples are more environmentally sustainable and, in the next three to four years, our goal is to reduce the CO2 produced in creating fabric samples – about 47,060 metric tons - by up to 80%, thanks to digital transformation.

Our digital services can transform your business with greater efficiency, cost savings and improvements in your sustainability efforts. Contact us today to discover how we can positively contribute to your enterprise’s future growth.