Digital Twin Technology: An explainer

Published by Admin on

Sep 13, 2021 11:04:50 AM

We offer a deeper understanding of digital twin technology and its applications in various industries

It’s astounding to reflect on the last 20 years to see how quickly technology has evolved and grown in value in our daily lives. Our phones are more powerful than computers from previous decades, fast food is being ordered online and delivered by drones, we can work from virtually anywhere and artificial intelligence has made self-driving cars a reality. Looking at all this technology, we see how important it is to understand these innovations to appreciate their value and impact.

Twinbru’s digital fabric twins are an innovation for the textile industry. But, digital twins aren’t as new as you might think. The aim of our digital fabric twins is to be a driver for the textile industry to embrace the advantages of digital technology and not only improve operational efficiency, but also boost sustainability and further innovation that takes the sector forward. As “digital twin” is fast becoming a buzzword in many, vastly different industries, let us explore the concept itself and how it could transform much of our world.

Back To The Future

The first idea of the concept of digital twins was postulated by David Gelernter in the 1991 book “Mirror Worlds”. It was Michael Grieves, however, who introduced the initial conceptual model of digital twins as part of his research on product lifecycle management for manufacturing.

When Grieves introduced the concept in 2002 it seemed unlikely to come to fruition as computer technology needed to catch up to the visionary idea. NASA embraced the concept and John Vickers gave it the name “digital twins”. The concept was used to create digital simulations of spacecraft for testing.“Why do I want to have a digital twin?” And why you want to have a digital twin is that it creates value.”

It then gained further traction when Gartner named digital twins in its Top 10 Strategic Technology Trends for 2017 and has kept focus on the technology in recent years.

Digital Twin Definition

Digital Twin Definition

Since its introduction to the world, digital twin technology has attracted attention in both industry and research, and is being used in more and more industrial applications.

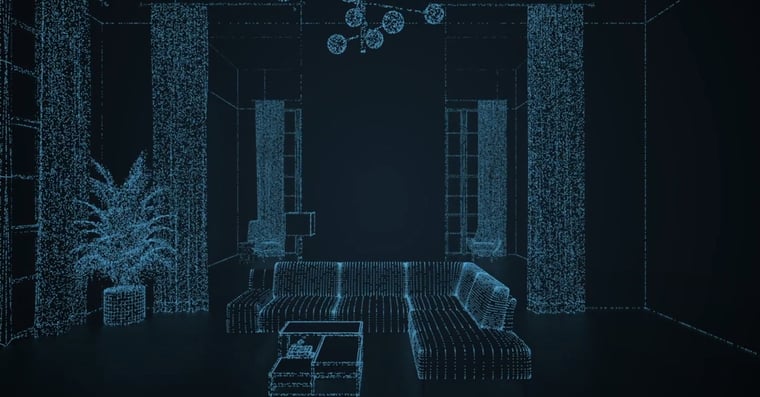

To simply define a digital twin, it is a digital representation of a physical object, process or service. It is the result of a computer program using real world data to create simulations that can predict how a product or process will perform.

Although digital twins exist today in many different categories, the conceptual model itself is a physical product in physical space, a digital representation of a physical product in a virtual environment, and the digital connection between the two in the form of data and information.

Digital twins are created using mathematical models with their complexity determined by the amount of data used for the model to simulate the real world object. The digital twin can then mimic and simulate the performance of the source object in a virtual world.

Real World Benefits

Real World Benefits

Digital twin technology has applications in a number of industries: manufacturing, aerospace, automotive, supply chain, healthcare, construction, retail, design and even utilities such as water supply.

Regardless of industry, digital twin technology is growing in demand. According to a strategic study, the global market for digital twins is expected to grow 38% annually to reach $16 billion by 2023. Looking at this predicted growth, it’s clear there are valuable benefits derived from the technology.

The benefits of digital twins may differ from industry to industry but include:

- Digital prototyping ahead of manufacture, reducing product defects and shortening time to market.

- Design customisation with the ability to create multiple permutations

- Improved product reliability and performance

- Reduced costs, particularly product development and manufacturing

- Increased efficiency by reducing risk and minimising time waiting for communication or data

In certain industries, a digital twin can virtually create typical challenges, thereby reducing reliance on real world testing. For example, digital twins can be used for fatigue testing, offer solutions for product lifecycle extension and even be used for things like modelling healthcare facilities to determine optimal traffic and workflow.

Here’s Why You Should Consider Digital Twins

Here’s Why You Should Consider Digital Twins

Digital twin technology has the potential for incredible impact on industries as it can drive innovation and performance.

Gartner predicts that, in the near future, billions of things will be represented by digital avatars. We see this already in Twinbru’s digital texture library of close to 11,000 different fabrics. This growth in digital representations can serve as a nexus where artificial intelligence, machine learning and analytics can allow companies to create computerised development cycles.

All the data gathered through these digital simulations can improve products, operations, services as well as improve customer experience and support the innovation of entirely new business.

As we sit on the cusp of an explosion of digital twin technology, it becomes even more important for the Fourth Industrial Revolution in key areas of automation, data exchange, analytics and forecasting.

“Digital twins are becoming a business imperative, covering the entire lifecycle of an asset or process and forming the foundation for connected products and services. Companies that fail to respond will be left behind.”

- Thomas Kaiser, SAP Senior Vice President of IoT

Part Of The Fabric Of The Future

Part Of The Fabric Of The Future

It may be that these big, exciting developments and applications of digital twin technology seem too future-forward for your business. As the innovator of digital twin technology for fabrics, Twinbru assures you it is not. It’s precisely what you need to future-proof your business and be on the leading edge for the digital era of business.

Our digital fabric textures offer you improved customer communication, digital assets for marketing or online retail, easy integration into digital design or website platforms and enhanced operational efficiency and workflow.

Contact Twinbru to explore how we can partner with you to close the imagination gap.